Exploring the Benefits and Techniques of Aluminum Casting in Modern Production

Aluminum casting has actually emerged as an essential strategy in modern manufacturing. Its lightweight residential properties enhance energy performance and decrease transportation expenses. Additionally, improvements in casting methods allow intricate layouts and fast prototyping. Nevertheless, the advantages extend beyond mere efficiency. The sustainability of aluminum casting processes provides considerable implications for various sectors. Understanding these facets can disclose the transformative impact of aluminum in contemporary production practices. What further developments could redefine its function?

The Lightweight Advantage of Aluminum Casting

Aluminum casting offers a significant lightweight advantage that is transforming sectors reliant on durable yet manageable materials. This property is particularly helpful in industries such as automobile and aerospace, where every ounce counts in efficiency and gas performance. The decreased weight of aluminum parts enables enhanced handling, lower transportation prices, and boosted power effectiveness throughout operation. Unlike much heavier steels, aluminum supplies a balance of strength and lightness, making it an excellent selection for facility applications that require high performance without sacrificing structural honesty. On top of that, the corrosion resistance of aluminum prolongs the life-span of actors elements, lowering the demand for regular substitutes. This mix of lightweight characteristics and sturdiness settings aluminum casting as a crucial innovation in modern-day production processes, urging advancement and supporting the advancement of advanced products that fulfill the developing needs of different industries.

Boosted Design Adaptability and Complexity

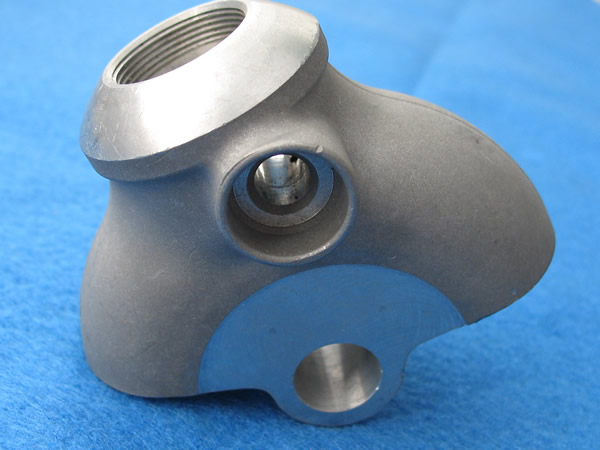

Layout flexibility and intricacy are markedly boosted with making use of aluminum casting, allowing manufacturers to develop detailed forms and forms that were formerly unattainable with traditional approaches. This ability allows the manufacturing of elements with comprehensive geometries, such as complex interior passages and thin-walled frameworks, which can significantly improve the efficiency of the end product.

Aluminum casting strategies, such as die casting and sand casting, help with quick prototyping, allowing designers to repeat and fine-tune their concepts promptly. The capability to generate tailored mold and mildews likewise adds to better positioning with details style needs, reducing product waste and reducing the need for substantial machining.

In addition, the light-weight nature of aluminum matches its layout adaptability, as it enables both visual allure and useful performance. Overall, the improvements in aluminum casting provide suppliers with the tools to press the boundaries of style, promoting technology across different industries.

Superior Thermal and Electric Conductivity

Aluminum's superior thermal and electrical conductivity makes it an important product in various production applications. Compared to various other metals, aluminum uses significant benefits, specifically in warm dissipation and electrical effectiveness. Aluminum Castings. This residential property enables its widespread use in sectors varying from auto to electronics, enhancing overall performance and reliability

Thermal Conductivity Advantages

An essential advantage of aluminum casting depends on its exceptional thermal and electric conductivity, making it an optimal selection for various applications in contemporary manufacturing. The high thermal conductivity of aluminum permits reliable heat dissipation, which is vital in industries such as automotive and electronic devices. Parts crafted from aluminum can effectively handle temperature variations, prolonging the lifespan of items and enhancing efficiency. This quality additionally makes it possible for suppliers to produce light-weight layouts without compromising thermal effectiveness. In addition, aluminum's capacity to hold up against thermal cycling additionally solidifies its placement sought after atmospheres. As markets significantly prioritize power effectiveness and performance, the thermal conductivity benefits of aluminum casting come to be progressively significant in driving innovation and sustainability.

Electric Conductivity Applications

The electrical conductivity of aluminum complements its thermal residential properties, making it a useful material in numerous applications within contemporary manufacturing. This conductivity makes it possible for effective power transfer, which is important in electric elements such as electrical wiring, connectors, and motherboard. Aluminum's lightweight nature even more enhances its charm in applications where minimizing weight is vital, such as in aerospace and auto sectors. Additionally, aluminum casting enables the creation of complicated forms, enhancing the efficiency of electrical tools. The product's resistance to deterioration and oxidation likewise adds to longevity in electrical settings, making sure reliability. On the whole, aluminum's superior electric conductivity placements it as a recommended option in markets that require high efficiency and efficiency in their electrical applications.

Contrast With Other Metals

While aluminum is renowned for its remarkable thermal and electric conductivity, it is important to compare its homes with those of various other steels to understand its benefits totally. Copper, for instance, displays even greater electric conductivity, making it more effective in particular applications like electrical wiring. Copper's weight and cost can limit its use. In contrast, aluminum provides a beneficial balance of conductivity, weight, and cost, making it suitable for many production applications. Additionally, aluminum's thermal conductivity is usually above that of stainless-steel and titanium, which are often used in high-temperature environments. Inevitably, aluminum stands out not only for its conductivity but likewise for its light-weight and corrosion-resistant homes, making it a flexible selection in contemporary production.

Cost-Effectiveness and Minimized Product Waste

Making the most of cost-effectiveness and minimizing material waste are vital advantages of aluminum casting in contemporary manufacturing. Aluminum's lightweight nature contributes to reduce delivery prices and power intake during production. Furthermore, its excellent recyclability implies that scrap product generated during the casting procedure can be recycled, considerably lowering the total material expenses.

Additionally, aluminum casting strategies usually permit complicated shapes to be generated with fewer secondary operations, which enhances the production process and decreases labor expenses. The capacity to create specific elements reduces the requirement for excessive machining, more reducing waste.

Firms embracing aluminum casting benefit from lowered manufacturing time and enhanced performance, bring about overall expense financial savings. This mix of reduced product costs, effective recycling approaches, and efficient manufacturing procedures positions aluminum casting as an economically beneficial option in the affordable landscape of contemporary production.

Technologies in Aluminum Casting Techniques

Recent innovations in aluminum casting techniques are changing the production landscape. Advancements such as the integration of additive manufacturing, enhanced mold designs, and environmentally friendly casting procedures are driving performance and sustainability. These developments not only enhance item top quality but additionally reduce ecological effect in the aluminum casting market.

Additive Production Assimilation

Additive manufacturing is changing aluminum casting strategies by enabling the production of intricate geometries and lightweight structures that were formerly unattainable. This assimilation enables manufacturers to utilize 3D printing modern technologies to create intricate molds and cores, which facilitate the casting of thorough layouts with improved precision. Furthermore, additive production decreases product waste and shortens preparations, making it an extra lasting and effective technique. Therefore, business can react a lot more swiftly to market needs and tailor items to fulfill particular customer requirements. This synergy between additive manufacturing and aluminum casting not only boosts design adaptability yet also positions makers to innovate constantly, driving innovations in effectiveness and product efficiency within the affordable landscape of contemporary production.

Enhanced Mold Design

As manufacturers look for to boost performance and product quality, technologies in mold design have actually emerged as a vital factor in modern-day aluminum casting methods. Advanced mold materials, such as silicon carbide and graphite, boost thermal conductivity and resilience, enabling faster cooling and boosted surface coatings. Furthermore, the integration of computer-aided design (CAD) technology enables precise mold geometries, promoting complex shapes that were formerly challenging to achieve. Innovations like 3D-printed molds additionally provide fast prototyping capacities, minimizing preparations considerably. Furthermore, modular mold and mildew designs enable simpler changes and repair work, decreasing downtime throughout production. Collectively, these improvements not only streamline producing processes but additionally add to the general quality of aluminum cast items, fulfilling the developing needs of various industries.

Eco-Friendly Casting Processes

While the aluminum casting market proceeds to progress, a growing emphasis on sustainability has brought about the advancement of green casting processes. These innovative strategies aim to minimize environmental impact by reducing waste and energy usage. One significant strategy involves using recycled aluminum, which pop over to this web-site considerably lowers the carbon footprint connected with resources extraction. Additionally, developments in mold materials and designs permit much more efficient heat transfer, reducing energy requirements during manufacturing. Water-based coverings and binders change standard solvents, in addition lowering dangerous discharges. Additionally, some makers are taking on closed-loop systems, making certain that waste products are reused within the production cycle. Collectively, these eco-friendly casting refines not only enhance sustainability yet likewise contribute to a more responsible production landscape.

Sustainability in Aluminum Casting Processes

Sustainability in aluminum casting processes has actually ended up being a centerpiece for producers intending to minimize their environmental influence. The industry is significantly taking on methods that minimize waste and improve resource performance. One considerable approach entails using recycled aluminum, which calls for only a portion of the energy needed to create brand-new metal from ore. This not just saves resources yet also lowers greenhouse gas emissions connected with manufacturing.

Furthermore, developments in modern technology have brought about more energy-efficient casting approaches, such as low-pressure and gravity casting, which enhance product usage and decrease energy intake. Suppliers are also carrying out closed-loop systems that permit for the recycling of scrap material generated throughout the casting procedure. Furthermore, the use of environmentally friendly finishes and lubricants additionally adds to an extra lasting procedure. On the whole, these initiatives show a dedication to ecological stewardship while keeping the top quality and effectiveness of aluminum casting

Applications of Aluminum Casting Throughout Industries

Aluminum casting discovers considerable applications across various markets as a result of its light-weight, strength, and versatility. In the automobile sector, aluminum castings are used to produce engine blocks, transmission housings, and wheels, boosting fuel effectiveness while decreasing exhausts. The aerospace market uses aluminum spreadings for architectural elements, gaining from their high strength-to-weight proportion, which is crucial for trip safety and efficiency.

In the customer electronic devices industry, aluminum castings are made use of for housing and structural components, providing sturdiness and aesthetic appeal. Additionally, the construction sector leverages aluminum spreadings for building aspects and fixtures, taking advantage of on their resistance to corrosion.

Furthermore, the aquatic sector includes aluminum spreadings in boat structures and engine components, reflecting its suitability for harsh settings. Generally, the diverse applications of aluminum casting emphasize its importance in modern production, adding to development and performance across numerous fields.

Regularly Asked Concerns

What Are the Common Alloys Utilized in Aluminum Casting?

The common alloys made use of in aluminum casting consist of 413, 356, and A380. These alloys are valued for their outstanding fluidness, strength, and deterioration learn the facts here now resistance, making them suitable for different applications in manufacturing and design.

Exactly How Does Aluminum Casting Contrast to Various Other Casting Approaches?

Aluminum casting offers special benefits over various other casting approaches, such as lighter weight, excellent deterioration resistance, and premium thermal conductivity. It likewise permits elaborate layouts and faster production times contrasted to standard products like iron or steel.

What Is the Common Life-span of Aluminum Cast Products?

The typical life expectancy of aluminum cast products varies, normally ranging from 20 to 50 years, relying on elements such as ecological problems, upkeep, and specific applications. Appropriate treatment can substantially extend their sturdiness and efficiency.

Are There Any Health And Wellness Threats Connected With Aluminum Casting?

The question of health dangers connected with aluminum casting arises as a result of potential exposure to aluminum dust and fumes. Prolonged inhalation may cause respiratory system issues, highlighting the relevance of appropriate precaution during the casting procedure.

Just How Can Defects Be Lessened in Aluminum Casting?

To minimize issues in aluminum casting, producers can execute rigid high quality control actions, optimize mold designs, maintain correct temperature Resources level control, make use of proper alloy structures, and apply efficient cleaning techniques to assure a defect-free casting procedure.